The purpose of the Mestrel (*) joint laboratory supported by CEA, the CNRS and the Protec Industrie company, is industrial scale development of organic surface treatment of metal, compliant with aeronautical standards and requirements.This process will improve protection against corrosion and paint adhesion.The French pre-painting surface preparation market represents about 35 million euros per year (**), including 3 million euros in sales for Protec Industrie.

The starting point for the method is the SEEP (***) electrografting process developed by a team at CEA Paris-Saclay, in a CEA-CNRS laboratory. This fundamental and applied research team has over the years acquired expertise in the physico-chemical mechanisms of use for surface treatments.The SEEP process consists in dipping the part to be treated in an aqueous solution. The coating obtained adheres strongly to the part via stable chemical bonds.The process complies with the principles of green chemistry.

The teams at the Mestrel joint laboratory are aiming to acquire greater experience of the process, already validated at laboratory scale, by overcoming a number of technological hurdles. Industrial scale development will enable large metal surfaces to be treated, such as an aircraft structure (fuselage panels and/or wing panel), while preserving bond primer (1st hurdle) and anti-corrosion (2nd hurdle) properties. The immersion phase will be replaced by a spray technique (3rd hurdle), which is less demanding and more economical in terms of the products used. These areas will be studied in parallel, with the aim of ensuring rapid release of the process to the market.

Protec Industrie could eventually add this treatment derived from SEEP to its industrial range, ensuring compliance with the very latest environmental and safety standards, while bringing down the corresponding costs and thus boosting competitiveness.The company is also looking to diversify its activities, more specifically towards treatment of aircraft wing panels, currently subcontracted owing to dimensional constraints. The potential uses of these processes could also include rail transport, the maritime sector (oil platforms, wind farms, etc.) activities in which corrosion protection is vital.

The marketing of this process developed by the Mestrel joint laboratory will enable Protec Industrie to grow in its sector of choice.

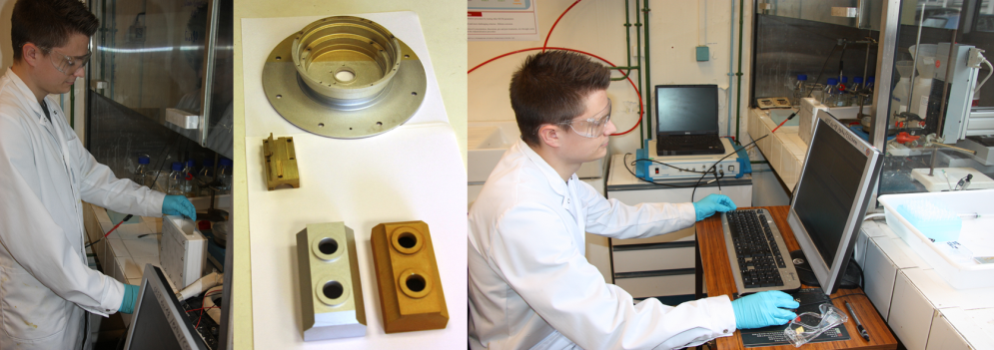

Left: implementation of the SEEP process - Centre: untreated aluminium parts and treated parts. Right: study by SECM (Scanning Electrochemical Microscopy) of the surface condition of treated parts. The Mestrel joint laboratory (CEA/CNRS/Protec Industrie) will develop this less polluting pre-painting surface preparation process for the aeronautical industry. © Credit L. Barbier- CEA

Doing without hexavalent chromium

Current surface treatments for metals, acting as the primer bond layer prior to painting and as anti-corrosion treatment, are based on chromium CrVI (6th oxidation state of chromium). Owing to its toxicity, the use of CrVI is currently banned by the European Reach regulations (****), but still tolerated under the terms of a waiver in certain industries until 2024. Most current alternative treatments replace CrVI by CrIII, but this is less effective as a bond and anti-corrosion primer. An alternative is today offered by sol-gel technology which however has a number of drawbacks: the limited lifetime of the coating before painting - less than 48 h - and the impossibility of reworking the paint after application.

The partners

The academic and industrial expertise of the two partners in the Mestrel joint laboratory complement each other:

- The Laboratory for innovation in surface chemistry and nanosciences (Licsen) at the CEA-CNRS Nimbe (Nanosciences and innovation for materials, biomedicine and energy) joint research unit in the CEA Paris-Saclay research centre, specialises in the surface functionalisation of materials and has extensive experience of technology transfer to industry.

- Protec Industrie is an SME employing 190 staff and is the surface treatment and special processes leader in France. An R&D hub was created in 2012, with the main aim of developing processes to replace those using CrVI and other toxic products.

(*) Mestrel : MEtallic Surface TREatment Laboratory, Labcom programme funded by the ANR (Convention ANR-16-LCV1-0001)

(**) sources of these figures: Protec Industrie benchmarking analysis

(***) SEEP: Surface Electroinitiated Emulsion Polymerization

(****) Reach: Registration, Evaluation and Authorisation of Chemical