Why characterise the nuclear fuel?

"Irradiated fuels contain extremely radiotoxic products, there's no point in denying it. Our laboratory is designed accordingly: the whole characterisation chain takes place in shielded cells with concrete walls one metre thick with even thicker lead glass windows. And everything is handled remotely." warned Jean Noirot, a CEA engineer. Numerous innovations depend on this "post-irradiation" characterisation. For example, the teams developed a fuel for the JHR by imagining a material based on uranium-molybdenum (UMo). They irradiated this material in reactor Osiris at Saclay then returned for analysis to Cadarache: "We then discovered the phenomenon of interdiffusion between the matrix and the fuel, as well as the formation of cavities at certain interfaces which caused the fuel to tear. Although this had been noticed in the initial tests in situ in Osiris, our analysis confirmed that the initial decision should be overturned, and therefore a more conventional fuel was chosen to start up the JHR. However, research is continuing into innovative fuel on an international level" Jean Noirot clarified.

Tools for microscopic observations of fuel resistance

To collect such detailed information in this extreme environment, the CEA teams have sophisticated resources. In the first place, optical microscopes adapted for testing radioactive objects are capable of collecting metallo-ceramographic data which highlights cracks and porosity in the irradiated material, as well as the existence of fission product precipitates.

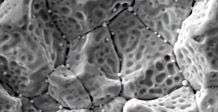

Observation of the gas bubbles from fission of the grains of irradiated uranium oxides © CEA

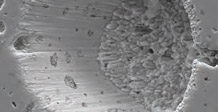

Crater formed artificially in order to analyse the gases contained in the bubbles © CEA

"

Porosity is an important phenomenon, both for fuel life, its behaviour in accident conditions and how it is stored before reprocessing" explains the researcher.

Microanalyses are also conducted with devices such as an electron probe (EPMA). It focuses an electron beam on the sample, which reacts by emitting X-rays. These are analysed by a spectrometer to reveal the nature of the elements present. A local analysis of the fuel composition is then possible. "We can then break up the pellet to see the surface of the grains, the joints or bubbles without the modification caused by polishing", Jean Noirot continued. "Seeing" actually means observing with a scanning electron microscope. In the coming months, the CEA will also gain a transmission electron microscope, a tool very commonly used to characterise materials which have already demonstrated their usefulness on non-irradiated fuels. Thanks to this, information will be accessible down to the scale of a nanometre.

All this and plenty of other data, both quantitative and qualitative, can thus help us assess the mechanisms controlling the fuel behaviour more accurately, and give comparison points for the models reproducing them.