Focus on the batteries of the future!

Three questions for Séverine Jouanneau, Head of the Department of Electricity and Hydrogen for Transport (DEHT) at CEA-Liten.

What part does CEA-Liten play in supporting the battery sector?

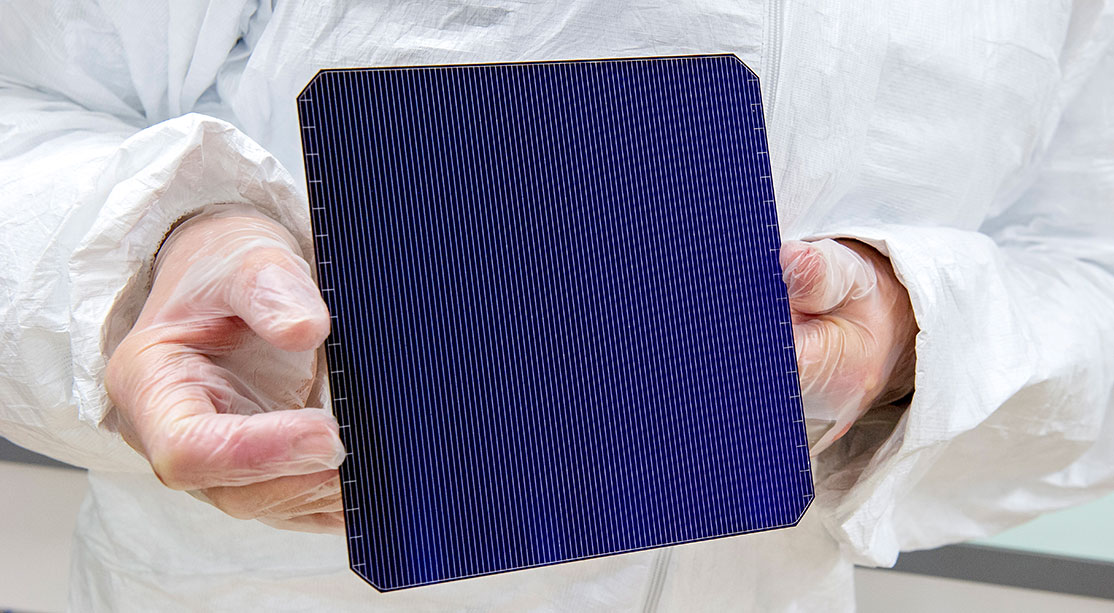

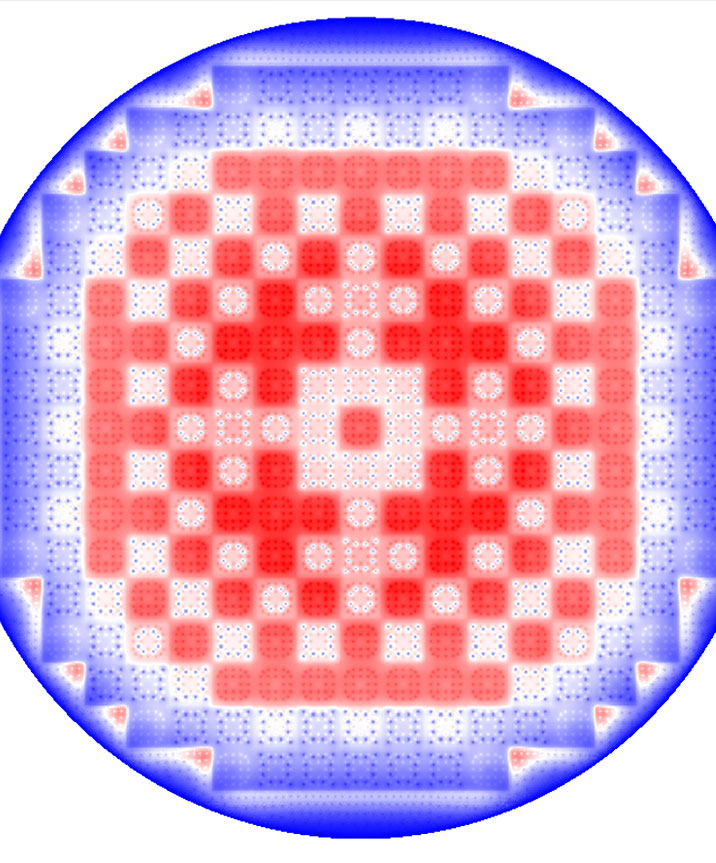

S. J.: Le CEA-Liten is part of a European initiative to support the battery sector, with an R&D support role for industry across the entire value chain. We are working in particular on improving materials for electrodes, manufacturing processes, electrolytes and chemistries, right through to the implementation of the technologies developed and their assessment on prototype cells. On the materials side, we are seeking, for example, to improve the lamellar components of positive electrodes in order to reduce the amount of cobalt used, and thus reduce their environmental impact. In all cases, it is a matter of detailed characterisation of the phenomena occurring at the interfaces in order to optimise them, which is crucial for improving performance.

What significant results were achieved in 2020?

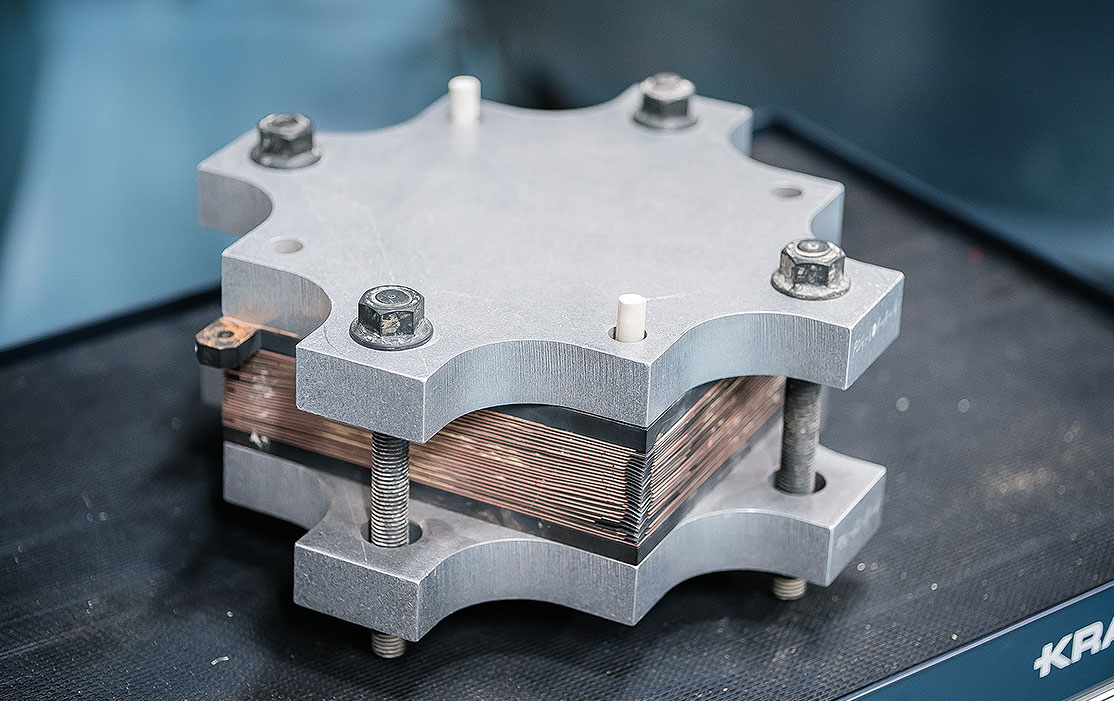

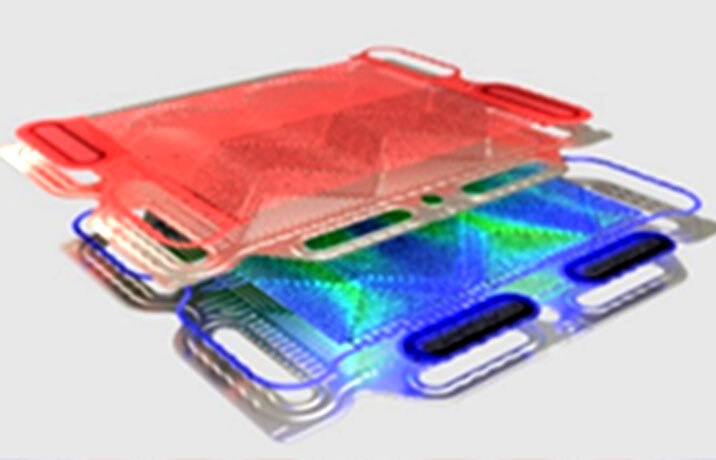

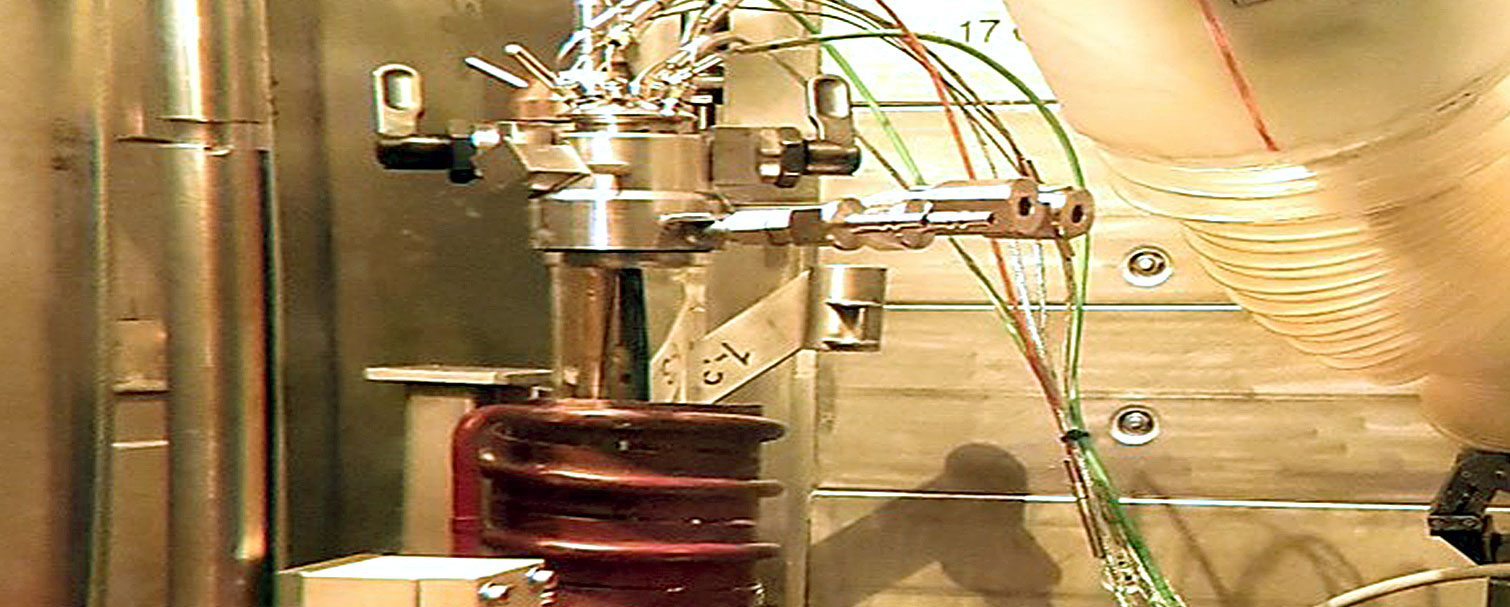

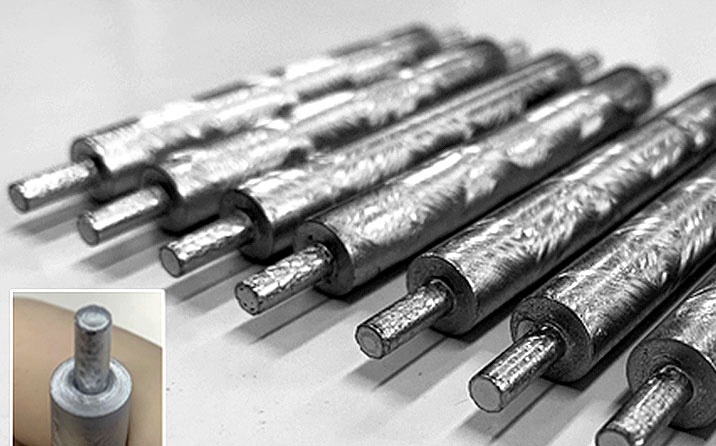

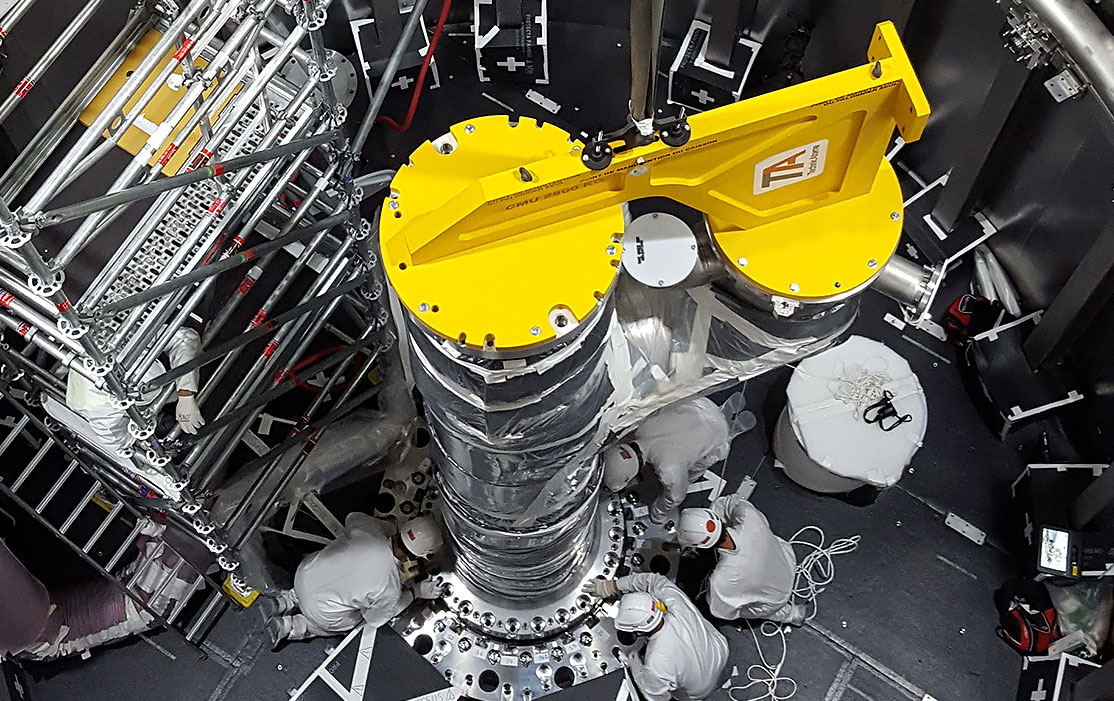

S. J.: In 2020, we successfully produced and implemented the first electrodes by extrusion rather than by coating! This process does away with the use of solvents that are toxic and difficult to reprocess. We have succeeded in getting as far as making the first cells, and the performance tests suggest results that match our expectations. On the materials side, we have identified several potential areas of work for developing hybrid or even solid electrolytes. These will enable us to design much safer and much more compact cells than is currently possible with current liquid electrolytes. Finally, in the field of electrodes, we have improved the performance of the existing materials and selected those which will be used in the first 3rd generation lithium-ion batteries which will be produced in French factories in 2023-2024.

What are the challenges ahead?

S. J.: Since the 3rd generation is just about ready, we are going to focus our efforts on the next generations. We have already identified potential electrolytes for the 4th generation, : we now have to select and implement that or those which will enable us to reach the industrial performance levels we are looking to achieve. There are still a few obstacles to overcome, such as managing the interfaces in a “totally solid” battery, to maintain good ion and electron conduction.

One of the things we are working on for future generations is innovative technologies such as lithium-sulphur chemistry, which will enable us to reach a new level in terms of performance. This research, and future developments, will be guided by the environmental impacts of the life cycle and the recycling of these products. This will apply when the components and processes are chosen, or even at the design stage.

CEA-Liten: One of the institutes in the CEA's Technological Research Division. Its role is the creation of solutions to address climate, energy and environmental issues.

Coating: Surface treatment consisting of applying a coating, which is generally liquid, to a substrate (paper, textile, plastic film, metal, etc., followed by drying and, if required, cross-linking (chemical or physical formation of one or more three-dimensional matrices).

3rd generation: 3rd generation lithium-ion batteries (and the next generations) have better performance levels than the first and second generations which are currently on the market, particularly in terms of energy storage.