Fuel cells as an efficient conversion technology, and hydrogen as a clean energy carrier, both have great potential - especially in the transport sector - to help fight carbon dioxide emissions, to reduce dependence on hydrocarbons and air pollution, and to contribute to economic growth.

To combat CO2 emissions from vehicles and help the development of Fuel Cell Electric Vehicles (FCEV), the European project COPERNIC1, an FCH-JU H20202 under the CEA’s coordination, has worked to significantly reduce the cost of "high pressure" tanks fitted to hydrogen vehicles.

A “success story” for Europe

A few years ahead of time, the COPERNIC project has already reached the 2020 target set by Europe to produce a tank of stored hydrogen for €600 per kilogram. The cost reduction was achieved using new materials, high-performance computing at the CEA and optimisation of the tank composite mass, an increase in the production rate and the use of a new integrated pressure management system. As a result, the price of hydrogen fuel cell electric vehicles will drop significantly and the distribution of these vehicles will be facilitated, contributing to combatting climate change in Europe and worldwide. That is why the European Union recognised the project as an R&D success story.

“COPERNIC’s tank costs five times less than other tanks available today,” summarises the project coordinator Stephane Villalonga, from the CEA.

The partners studied innovative solutions in terms of materials, manufacturing processes, instrumentation and storage systems to:

- Increase the performance of the 700 bar composite tanks used for the storage of hydrogen fuel cell electric vehicles;

- Reduce the development and manufacturing costs of the hydrogen tanks.

The CEA has shown, for example, that the mass of the composite could be reduced by 20% and that the winding time of the tank could be reduced by half.

1 COPERNIC stands for “COst & PERformaNces Improvement for Cgh2 composite tanks.”

2 The Fuel Cells and Hydrogen Joint Undertaking (FCH JU) is a unique public private partnership supporting research, technological development and demonstration activities in fuel cell and hydrogen energy technologies in Europe. Its aim is to accelerate the market introduction of these technologies, realising their potential as an instrument in achieving a carbon-clean energy system.

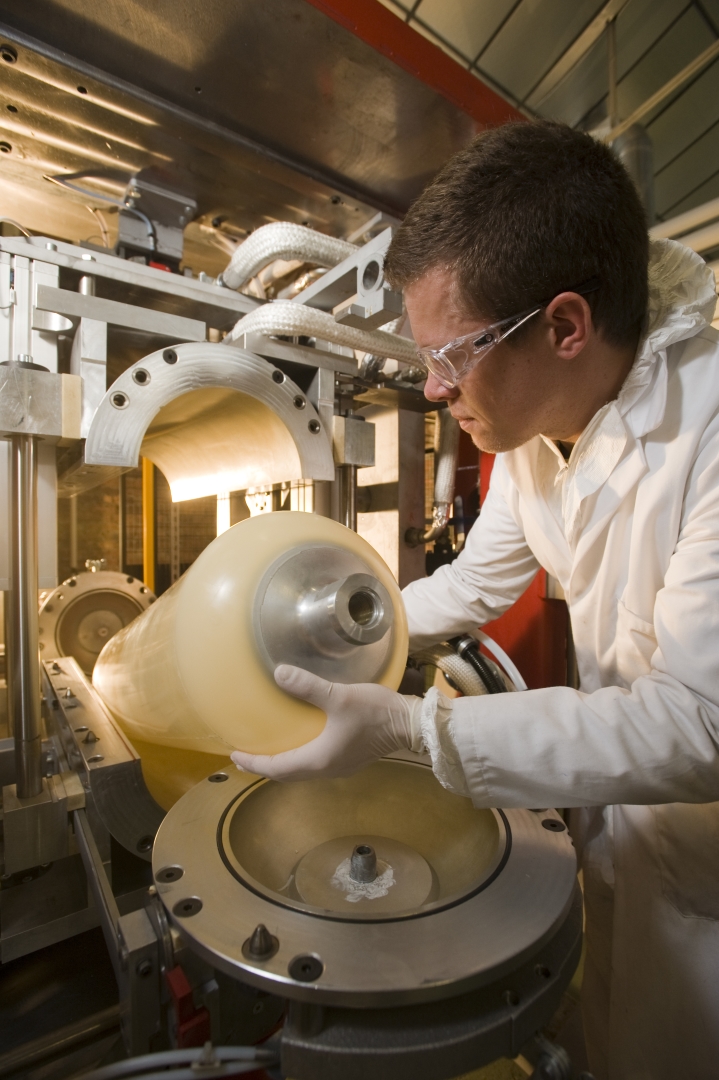

Robot winding a hydrogen tank at the CEA labs. © CEA

Driving under the CEA coordination because…

The CEA, especially at its Le Ripault Centre, is at the vanguard of high-performance and energetic materials, as well as for polymer and composite chemistry and processing, and particularly for 700 bar compressed gaseous hydrogen storage in full composite vessels. The CEA has gathered extensive knowledge on materials and processes for vessel manufacturing, enhanced FE (Finite Element) models for calculation and optimisation of vessel design (virtual testing), on homologation testing and health monitoring, leading to developing a full composite tank highly instrumented for testing. This expertise helped in optimising the design and enhancing the materials and components. The CEA's facilities make it possible to test the tanks in accordance with the EC79 and GTR13 regulations (up to 300 L).

From a European R&D project to your car

The consortium reached its main objectives and thanks to the COPERNIC project results, several partners continued their work in the European project HiPHONE, developed as part of KIC InnoEnergy in Grenoble. They are designing, manufacturing and commercialising a hydrogen tank of 62 L for FCEV, respecting the European regulation EC79, which should be accredited in September 2018. COPERNIC has also launched a series of international conferences on hydrogen tanks, PHASE, its third and latest edition was held on 15 and 16 May in Tours (France), close to the CEA Le Ripault centre.

A liner manufacturing equipment at the CEA Le Ripault Centre. © P. Stroppa/CEA

About COPERNIC

Running from June 2013 to November 2016, COPERNIC brought together, under the coordination of the CEA, 2 RTOs and 5 manufacturers from 5 European countries. Receiving a €3.5M grant from the EU, the project ensured that the deployment of Fuel Cell Electric Vehicle is not inhibited by prohibitive high-pressure tanks cost or availability. The ongoing European project HiPHONE, developed within the KIC InnoEnergy, is building on COPERNIC’s results.

CEA Extreme Temperature Cycling Facility (up to 300 L, 1100 bar, -60°C, +100°C) © CEA