Real-time industrial process quality and safety monitoring for better, faster, cleaner, and cheaper production

iUMTEK analyzers identify the chemicals present in a liquid, solid, or gas 10 to 30 times faster than laboratory analysis and with results that are more representative of the medium being tested.

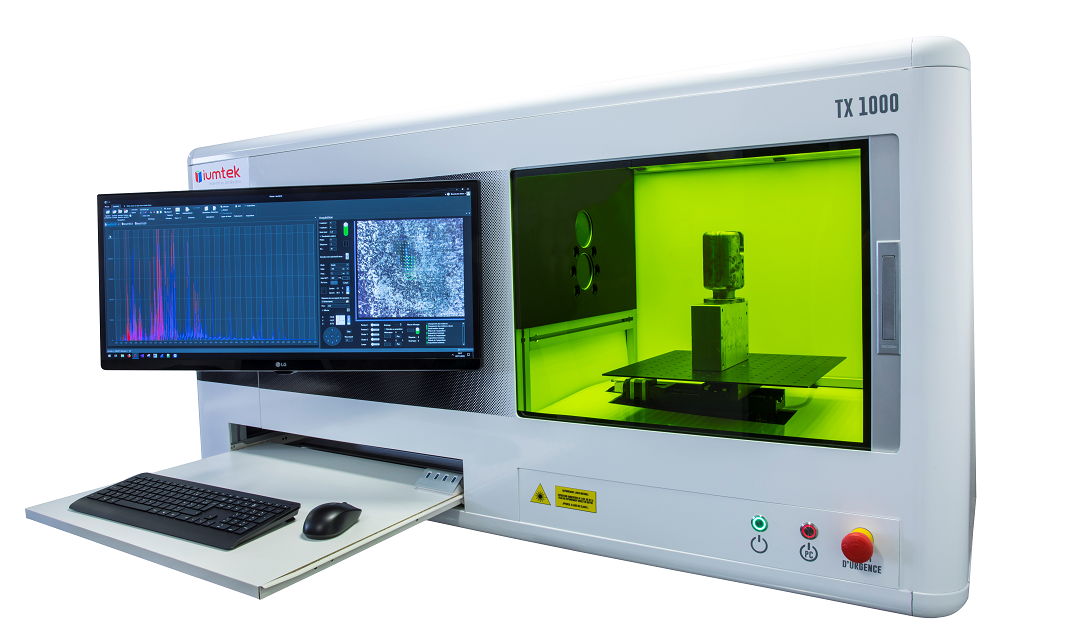

The LIBs TX 1000 analyzer from iUMTEK - courtesy of Alain Béguerie

The startup iUMTEK employs an analytical technique that NASA uses for its Mars rovers: LIBS, or laser-induced breakdown spectroscopy. Based on more than 25 years of R&D by the CEA and Orano, LIBS is helping industrial customers test liquids, solids, and gases.

No sampling or sample preparation is necessary to do a test, and the results are more representative of the medium being tested than laboratory analysis. The analyzer works at distances of up to several meters and in a range of configurations: above a molten bath, through a window, or even inside a vessel. Each chemical present is identified and quantified, so that the exact composition of the medium can be known.

iUMTEK has sold several devices to research centers for diagnostic use. At the same time, it is developing a solution for in-line industrial process monitoring. One potential use would be for companies that use recycled raw materials in their manufacturing processes to check the composition of the materials upline from the process.

iUMTEK is developing this technology for new use cases as part of an R&D agreement with the CEA. It also holds licenses to five CEA LIBS patents.

Key figure: 118

The iUMTEK analyzer is the only one capable of identifying the 118 elements of the Mendeleev periodic table using the same instrument, regardless of the phase of the material analyzed

Key markets:

- Government and private-sector research centers

- Small Modular Reactors (SMR/MSR)

- Metallurgy

- Recycling

Technology used:

- Laser ablation of liquid, solid, or gaseous material

- Emission spectroscopy analysis

- Artificial intelligence

Year founded: 2017

CEA institute: Energy Division