Choosing a closed fuel cycle

France’s strategy is built on a sustainable approach to nuclear energy, leading to the choice of recycling, says Bernard Boullis, director of the programme on the “back-end of the nuclear fuel cycle” in the CEA Nuclear Energy Division.

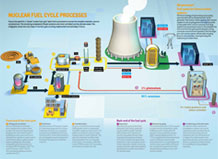

It is therefore important to provide the best responses to the issues related to the availability of natural uranium resources and the management of ultimate waste. For a better understanding of these issues, it is of interest to review what goes in and what comes out of our existing nuclear reactors, or pressurised water reactors. “Normal” fresh fuel contains about 4% fissile1 uranium-235 (235U), with the remainder being uranium-238 (238U). On removal from the reactor, the fuel still contains most of the

238U and part of the initial

235U, together with

fission products that are highly radioactive with a lifetime of about a century. It also includes 1% of plutonium and 0.1%

minor actinides. However, these radioactive elements will still be present after tens of thousands of years. What, then, can be done with the reusable materials (uranium and plutonium) and the unwanted toxic elements?

Countries that have decided to abandon nuclear power in the near future have logically opted for a “once-through fuel cycle”. In plain language, this means that spent fuel is considered entirely as waste and destined for permanent disposal in a deep geological repository. This was the option in Sweden, for example, after its decision not to build any new reactors. Conversely, the “closed fuel cycle” (with recycling of spent nuclear fuel) makes sence in countries such as France or Japan, and tomorrow China and India, that wish to ensure sustainable nuclear energy. Uranium and plutonium are therefore extracted from the spent fuel to be recycled in fresh fuel assemblies. Only the fission products and minor actinides, considered as ultimate wasteforms, are

vitrified for disposal2.

Spent fuel storage pool at La Hague © Areva/JM Taillat

The result: a much smaller waste volume with a radioactive impact divided by ten because the plutonium has been removed. France had a pioneering role in this area: the CEA Nuclear Energy Division developed the reprocessing technologies that are used today in La Hague plant. China is now following a similar route and is interested in French technology.

MOX: the first step in recycling

In current practice, the closed fuel cycle consists in blending the recovered plutonium with depleted uranium3 to obtain

MOX, which will then be supplied to reactors as fuel. Unfortunately, this only works once: spent MOX fuel contains plutonium isotopes4 that are difficult to reuse in existing PWRs. In addition, this option does not resolve the long-term problem of resources because the performance of MOX is comparable to that of conventional fuel: only 1% of the potential energy contained in natural uranium was actually “burned”. If nuclear energy is to achieve sustainable development, the “easily” exploitable natural resources may be unable to meet the need beyond a few decades. The solution is to find a way to use

238U (99.3% of natural uranium). Recycling as MOX in light water reactors must therefore be considered as a first step intended to make the best use of available resources in existing reactors, and to condition the ultimate wasteforms as well as possible, while preparing for the future. “Once through a MOX reactor lasts about fifteen years, then it will be up to 4th-generation fast neutron reactors (FNRs),” adds Bernard Boullis.

1 The nucleus of a fissile atom can be split in a neutron flux, releasing a large amount of energy.

235U is the only natural fissile element. On the contrary,

238U — by far the most abundant — is not fissile but fertile: it can form fissile elements after neutron capture.

2 Many countries have not yet formulated a national policy, and store spent fuel in a reversible manner. This is the case of the USA, for example.

3 Residual uranium after enrichment, containing practically no

235U, which was extracted to fabricate nuclear fuel (“enriched” in

235U).

4 The nuclei of the different isotopes of an element all have the same number of protons (characteristic of that element) but not the same number of neutrons:

235U and

238U are uranium isotopes, for example.

Fast reactors: the path toward nuclear energy for the future

These reactors are capable of using all the isotopes of plutonium, which allows the fuel to be recycled repeatedly. The plutonium burned in the process can also be directly regenerated in the reactors through the capture of fast neutrons by

238U. The production rate can even be adjusted: the reactors can produce more than they consume (“breeding” mode); or they can “burn” the excess (“burner” mode); or they can produce as much as they consume (“isogenerator” mode). CEA is developing the third option. In this case, after initially fueling the reactor with plutonium recovered by reprocessing MOX, the operating FNRs will then produce their own fissile material until depletion of all the initial 238U. FNRs are capable of generating 100 to 150 times more energy from natural uranium than existing reactors. The known uranium reserves would then become the largest natural energy resource — well ahead of fossil hydrocarbons. “Over the very long term, France could even dispense with mines, since the depleted uranium already stockpiled in the country would be sufficient for several thousand years of electricity production,” remarks Christophe Poinssot, head of the CEA Nuclear Energy Division Radiochemistry & Processes Department at Marcoule.

Another advantage: fast reactors generate about four times less minor actinides than thermal neutron reactors, while producing the same amount of electricity. Above all, they can “burn” these elements to obtain fission products with much shorter half-lives. This process, known as transmutation, has been a subject of extensive research in the last two decades in France by the CEA, as well as in Japan and the United States. The radioactivity of the ultimate waste — consisting mainly fission products without minor actinides — would decrease to a level comparable with that of uranium ore within three centuries instead of tens of thousands of years: “This brings us back to a time scale compatible with history and human memory” notes Christophe Poinssot.

Meanwhile, the CEA, which developed all the current reprocessing technologies before transferring them to Cogema (now Areva), continues to improve the processes implemented at La Hague. At the same time, teams at Saclay, Marcoule and Cadarache are now developing the fuel cycle of the future.