Processing and recycling of spent fuel currently

Since 1987, EDF has supplied about twenty reactors with MOX in fuel assemblies containing one-third MOX and two-thirds UOX. Plutonium thus generates about 10% of the nuclear electricity in France. “By adopting the closed fuel cycle, France no longer stockpiles plutonium in the final waste: it is all recycled as MOX” says Christophe Poinssot. Each year, French nuclear power plants thus generate only 50 tonnes of ultimate waste compared with 1,200 tonnes for a once-through fuel cycle; the 200 tonnes of spent fuel (MOX and ERU -Enriched Reprocessed Uranium- are stored temporarily before its subsequent use.

In France, the back-end of the nuclear fuel cycle — extraction of uranium and plutonium from spent UOX fuel, MOX fabrication with the recovered plutonium, vitrification of ultimate waste — is fully operational in La Hague and Melox plants, based on technologies created mainly by CEA1. The processes are so efficient that more than 99.9% of the plutonium is currently recovered. Contaminants represent only a millionth or even a billionth of the initial amount. Does this mean that all the processes have been finalised?

Optimising waste vitrification processes

“The performance is already outstanding, but CEA is pursuing its R&D in close cooperation with AREVA. The objective is to adapt the processes to new fuel developments. We also want to optimise them in order to obtain the same results at lower cost and further optimise ultimate waste management” adds Bernard Boullis. Most of this work is carried out at Marcoule. For example, the extraction and purification of plutonium and uranium — as effective as they are now — are performed in three steps in three different facilities. “We are working on a new approach that would allow everything to be accomplished in a single step, in a single facility, with smaller amounts of chemicals that would diminish plant discharges” explains Christophe Poinssot.

Reconfigurable vitrification prototype of the nuclearized cold crucible melter at Marcoule © P. Dumas/CEA

1 Today, Areva is the only producer of MOX fuel in the world.

2 Under France’s government borrowing initiative sponsored by the Prime Minister through the Environment and Energy Management Agency.

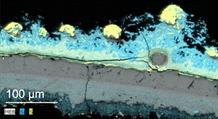

Corrosion products formed on the surface of a steel sample corroded in situ at 85°C for 19 months in the clay tunnels of Andra's deep geological repository laboratory in the Meuse / Haute-Marne © CEA

Once the plutonium and uranium have been recovered, the ultimate waste — fission products and minor actinides — is calcined, vitrified, and poured into “packages” intended for deep geological disposal. Although the packages themselves are fully defined, optimisation of the processes is still possible. The molten glass containing the waste is typically produced at temperatures above 1,000°C in metal melting pots that are damaged by corrosion and heat, and must regularly be replaced, resulting in technological waste that must then be managed.

Marcoule has developed a new technique that was implemented in 2010 on one of the six vitrification lines at La Hague: the “cold crucible melter.” In this process, the metal wall of the melting pot is water-cooled. The crucible is filled with glass that is melted by induction before the waste is added. A thin layer of solid glass forms in contact with the cold wall, separating the melter wall from the molten glass and radioactive waste. The crucible is protected from the heat and radiation, and thus lasts much longer and can be used to melt more corrosive materials.

A new process for MOX production waste

Another development project is being conducted by the CEA2, in liaison with Andra (French National Radioactive Waste Management Agency) and Areva: the treatment and conditioning of solid technological waste, a mixture of metals and organic matter (vinyl, polyethylene, polymer gloves) from the Melox plant, which produces MOX. Although much less radioactive than spent fuel waste, it must nevertheless be stored in suitable packages. This is where an innovative process, called Pivic, could be used to treat and condition the waste in a single step. The waste is introduced in a furnace and incinerated by a plasma torch on a molten glass bath; the ashes are incorporated into the glass and the molten metal sinks to the bottom of the crucible, which constitutes the primary waste container. “This process, now under developed, draws on all our skills and knowledge: incineration by plasma torches, vitrification, induction melting, off-gas treatment, etc.” says Luc Paradis, head of the CEA Waste Treatment and Conditioning Research Department. Development work on Pivic, which is expected to begin operating at La Hague during the next decade, now mobilises about fifteen people at Marcoule.

In general, CEA teams provide ongoing support to Areva for upgrading La Hague plant. These experts regularly intervene on the site — often using numerical simulation codes of the plant developed by the Nuclear Energy Division — to examine issues such as shutdown and restarting, or equipment ageing. “This plant will be here for a long time, but we are already working on innovative processes for future plants” adds Christophe Poinssot.

The end of the fuel cycle: waste storage and disposal

In 2006 Andra was assigned the task of designing and implementing an industrial geological repository site (Cigeo). The waste will be shipped to the site in “packages”. The CEA has largely contributed to their design, and continues to conduct studies in liaison with the industrial partners that produce the packages in order to provide Andra with extensive data on their long-term behaviour, and especially their evolution during the coming millennia under repository conditions. The CEA carries out accelerated ageing experiments on inactive and radioactive glass samples (at Marcoule in the Atalante complex) to identify the physical and chemical alteration mechanisms. As these experiments alone are not sufficient to extrapolate the long-term behaviour of the glass in a geological waste repository, other studies are conducted on natural analogues (volcanic rocks) and archaeological analogues (ancient glass specimens found on the Mediterranean sea bed). The results are used to develop and qualify mathematical models describing the evolution of the packages. “They show that the package lifetime in an underground repository of the type currently envisaged for the Cigeo project should exceed several hundred thousand years” concludes Luc Paradis.