The information and communication technologies sector has been growing rapidly for three decades, driven by strong consumer demand and remarkable technological progress. At the same time, for several years now, societal demand for controlled growth that respects the environment has emerged and has become an integral part of the public debate. How can these two aspirations be reconciled, beyond imprecatory formulas? At IRIG, where researchers are working on future generations of memories for quantum technologies or future processors for the Internet of Things, a research team has asked itself the following question: what is the environmental impact of the memories it develops?

RIG researchers have carried out a comprehensive review of the sustainability of perpendicular magnetised memories, a low-power storage technology. Supply-critical materials such as cobalt (Co), ruthenium (Ru), tantalum (Ta) and platinum (Pt) are used to various degrees in their composition. Taking into account the quantity of material used per device, platinum, 80% produced by South Africa and Russia, presents the greatest risk (geostrategic, environmental, economic, etc.). However, according to the study published by IRIG researchers, the economic and environmental cost of a memory is dominated by the silicon substrate. A memory contains 127g of silicon, compared to 3.4mg of platinum.

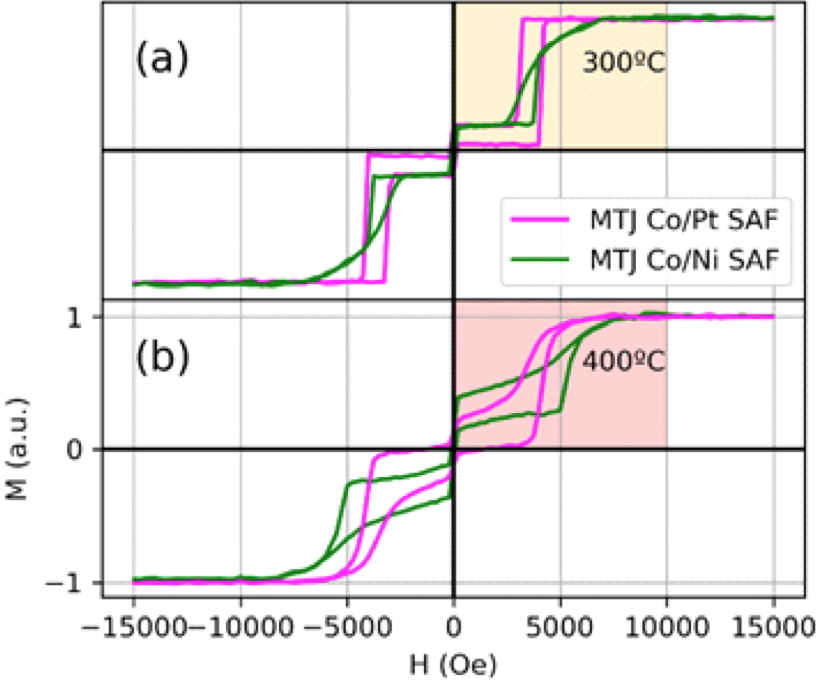

However, it is interesting, in order to reduce any dependence, to substitute the platinum used in the Co/Pt

multilayer with a Co/Ni multilayer in the

reference layer of a magnetic random access memory (MRAM). Nickel is not a rare metal and therefore does not present any risks in its supply. The researchers' results (

Figure) show that it is possible to change the composition of the reference layer [Co 0,5nm/Pt 0,25nm]

xN by a layer of composition [Co 0,18nm/Ni 0,55nm]

xN while retaining the same magnetic properties and thermal stability. Furthermore, the substitution of platinum for nickel does not require the use of other critical materials. A reduction in the global warming potential of the reference layer by a factor of 3 can therefore be achieved.

A wider use of MRAMs by the microelectronics industry can therefore be envisaged in a sustainable way by replacing platinum with nickel and potentially reducing the availability risks.

Substituting the Co/Pt multilayer with a Co/Ni multilayer in the reference layer of an MRAM does not lead to a degradation of the thermal stability.

Substituting the Co/Pt multilayer with a Co/Ni multilayer in the reference layer of an MRAM does not lead to a degradation of the thermal stability.

A multilayer is a layer that is a repetition of a basic pattern. For example [Pt/Co]N where N is the number of repetitions of Pt/Co.

Schematically, a magnetic memory consists of two magnetic layers separated by a non-magnetic layer. One magnetic layer, called the reference layer, has a fixed magnetisation. The orientation of the other magnetic layer is free. When the magnetization of both layers is in the same direction the memory is in the "zero" state. When the magnetization of the free layer is turned in the opposite direction then the memory is in the "one" state.