This project is divided in two main parts:

- Durable waste form conditioning matrix formulations and studies, laboratory scale (100 gr), bench scale (1kg) and near-industrial scale (100 kg) tests are led in France at the CEA Marcoule laboratories and technological platforms,

- Feasibility studies for process implementation, operation and maintenance principles and waste disposal are led by Orano teams.

Laboratory tests and part of bench scale tests have already been performed with success and near-industrial scale tests are under way. Feasibility studies will follow, in order to deliver complete results before end march 2019.

In this project, technical and commercial interfaces in Japan are ensured by ANADEC, a joint venture between Orano and ATOX, a Japanese company specialized in nuclear services and maintenance.

The CEA and Orano have developed vitrification processes and operated industrial vitrification facilities in France and abroad for more than 40 years, with rare expertise on formulation and long-term behavior of glasses for encapsulation of nuclear waste.

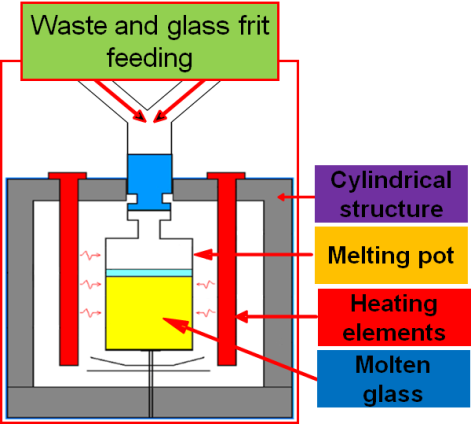

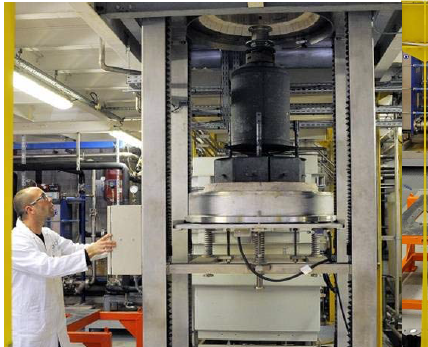

In-can

prototype developed at the CEA Marcoule (France). © CEA/DR