Liten possesses unrivalled know-how

assembling materials deemed impossible to assemble, with two decades of

experience in diffusion welding, a solid-state welding process that leverages

the diffusion of atoms between two materials to create a joint. The process

entails applying high temperature and pressure to the two parts to be

assembled. This can be done simultaneously or not, according to a predetermined

cycle. Liten’s researchers know how to adjust the process for each unique

combination of materials, verify the process using models, scale up the process

for use in industrial settings, and transfer the process to partners.

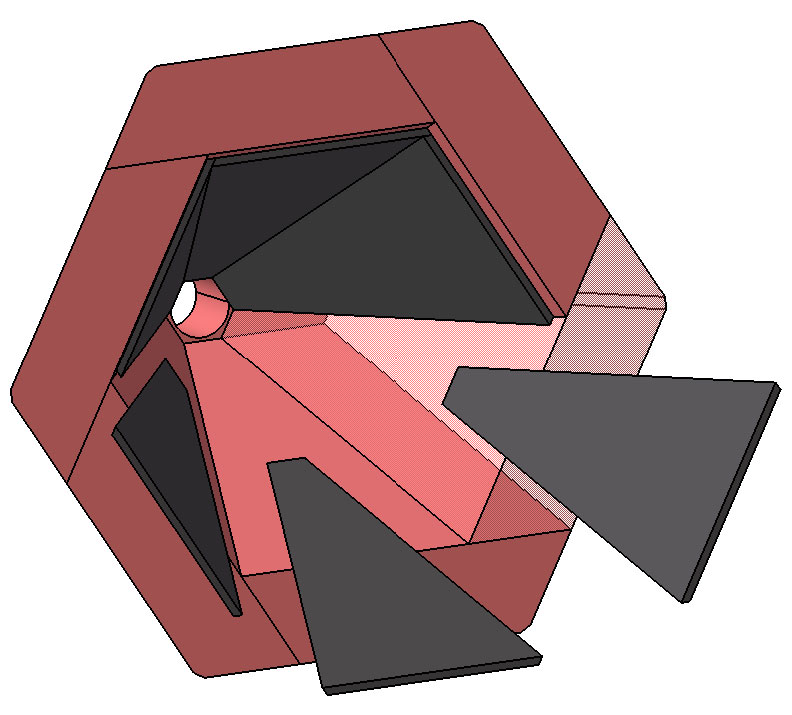

Liten researchers were asked by their

colleagues working on the ITER reactor project to assemble a complex part from

basic tungsten and copper components—the two metals are impossible to weld

together using traditional techniques. To create the joint between the two

metals, the researchers used an intermediary material chosen for its capacity

to control the underlying diffusion mechanisms. They also determined the best

process for assembling the particularly complex part, which contained tubes and

several other internal components made from other metals.

This unrivalled know-how

can help drive advances in the aerospace, nuclear, glass, plastics, chemical

(reactors), new energy technology, energy-efficiency (heat exchangers), and

other industries.

© V.GUILLY/CEA