KEY FIGURES

€6 million in investment

700 sq. m facility plus

a 120 sq. m outdoor testing area

Grenoble

|

The Hydrogen Production and Storage Platform is home to:

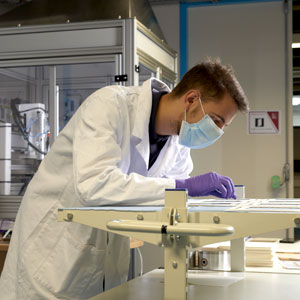

A SOEC/SOFC stack pilot line

that covers all process steps: preparation and implementation of the contact layer and seal using chemicals, tape casting, and robotic seal assembly; mechanical techniques like laser engraving; plus crucial quality inspections of each component before the stacks are assembled.

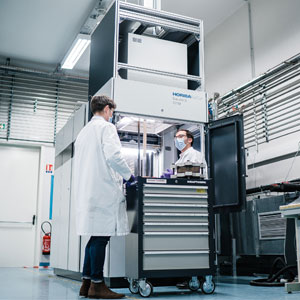

The line also handles packaging and stack performance testing. The total production capacity is 1-2 stacks per week. The equipment is flexible enough to use to develop new generations of stacks and can also be used to improve the reliability of manufacturing processes. A performance and durability testing area

is used to characterize single SOEC/SOFC components, cells, stacks, modules, and systems in conditions representative of the target applications. Performance and durability testing can be done in electrolyzer (SOEC), fuel-cell (SOFC), reversible (rSOC), and co-electrolyzer (co-SOEC) modes. Durability tests are carried out over several thousand hours. The platform's other research instruments include chromatography and electrochemical impedance spectroscopy to provide deeper insights into the objects being investigated. |

The platform also has state-of-the-art facilities for the development of hydrogen storage technologies:

-

Pressurized gas storage: Hydrogen is compressed to 700 bars in tanks. This type of storage can be used on board a fuel-cell-powered car.

- Hydrogen can also be stored in its liquid state, which maximizes the amount of fuel that can be stored in a small volume. At atmospheric pressure, hydrogen is liquefied at −253 °C. This means it can be stored in a cryogenic tank at low pressure. Liquid hydrogen storage, currently limited to space and aeronautics applications, is the subject of substantial research and development.

- In chemical storage, a liquid organic hydrogen carrier (LOHC) is used. These organic compounds have the ability to absorb and release hydrogen through chemical reactions. Research on chemical storage, an alternative to pressurized gas or liquid storage, is also very active.

|

|