The global technology roadmap (ITRPV)

indicates the expected improvements and market evolution in the coming years,

technology axis by technology axis, and market by market.

It estimates that 165 mg of silver is

currently deposited on M6 (166x166 mm²) heterojunction cells, equivalent to 147

mg in M2 (156.75x156.75 mm²) format. It also indicates an efficiency of 24.5%

for these cells in 2022, which represents a power of 5.98 W per M2 cell, and a

ratio of amount of silver consumed per watt of 24.58 mgAg/W.

Our metallization experts are working to

reduce material consumption and continuously improve the printing processes of

the collectors on the surface of the photovoltaic cells. They have identified

several ways to achieve the expected targets in their field.

They have recently demonstrated the

possibility of reducing the width of the metallization lines, produced by

screen printing, by using screens with thinner openings than the standard, while

ensuring the transfer of the silver paste and low line resistance. This

required considerable work to optimise the process.

The result: CEA has produced heterojunction

cells in M2 - 6 busbar format, with a material consumption lower than the

values estimated in the international ITRPV 2022 roadmap.

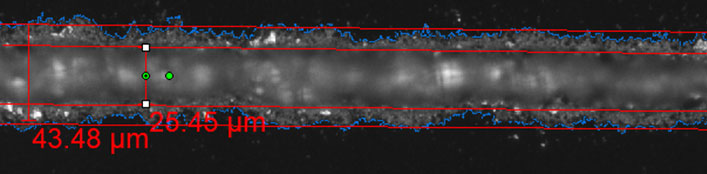

Microscopic measurement of metal line widths

Performing the screen deposition process with screens having such thin openings can generate bad silver paste transfers, and thus lead to significant losses in efficiency if not properly optimized. But the efficiency of the cells obtained after silver reduction remained at a good level, with a loss of -0.08% absolute compared to the CEA reference cells.

The ratio of silver consumed per watt achieved is therefore 19.2 mgAg/W instead of 24.58 mgAg/W (ITRPV 2022) - which is the level of material consumption expected by the international community by 2026 for this technology. Such performance is not expected in production until 2029, again according to ITRPV2022, which places CEA at the state of the art of screen printing metallization processes applied to the heterojunction cell.

The CEA is also seeking to replace silver with other conducting materials while ensuring their compatibility with assembly into reliable and long-lasting photovoltaic modules.