The Transverse Skills Program "Dynamic Fragmentation of Ice" (PTC DeFI) consists of studying the fragmentation of cryogenic solids intended to mitigate plasma disruptions in the ITER reactor. In this context, a preliminary study was conducted using water ice pellets impacting a rigid target. The results of this work, conducted jointly with the Institute of Geosciences and the Environment (CNRS) and the Soils, Solids, Structures, Risks Laboratory at the University of Grenoble Alpes (UGA) have just been published in the International Journal of Impact Engineering [1].

The first step of the PTC was to study, under the same experimental conditions as cryogenic solids, a material that is better known in the literature, namely water ice. Ice cubes similar in size to those required for ITER (Ø = 28.5 mm and L = 57 mm) were produced at the IGE and then tested at the 3SR laboratory. In addition, simulations were carried out using the DFH-KST code, which already existed for other fragile materials such as concrete and ceramics.

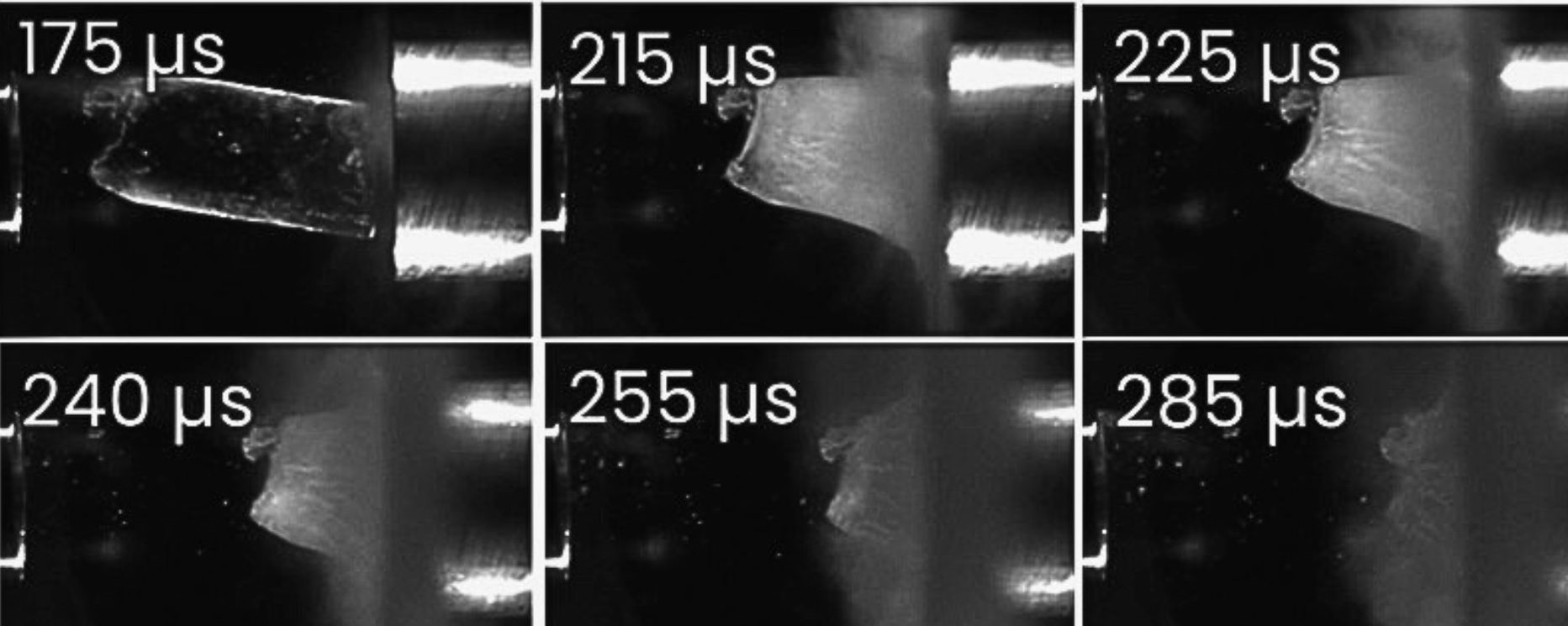

The water ice pellet manufacturing process developed by IGE allows for control of grain size and porosity. The structure produced was verified by X-ray tomography. Direct impact tests conducted at 3SR used the Hopkinson bar method, which is based on the propagation of elastic waves in solid materials. Using a gas gun, the water ice pellets are projected at 30 m/s onto an aluminum bar. The impact produces an elastic strain wave in the bar, which is measured over time using strain gauges. Simultaneously, the propagation of cracks in the water ice pellets is captured using a high-speed camera with an acquisition frequency of 200 kHz.

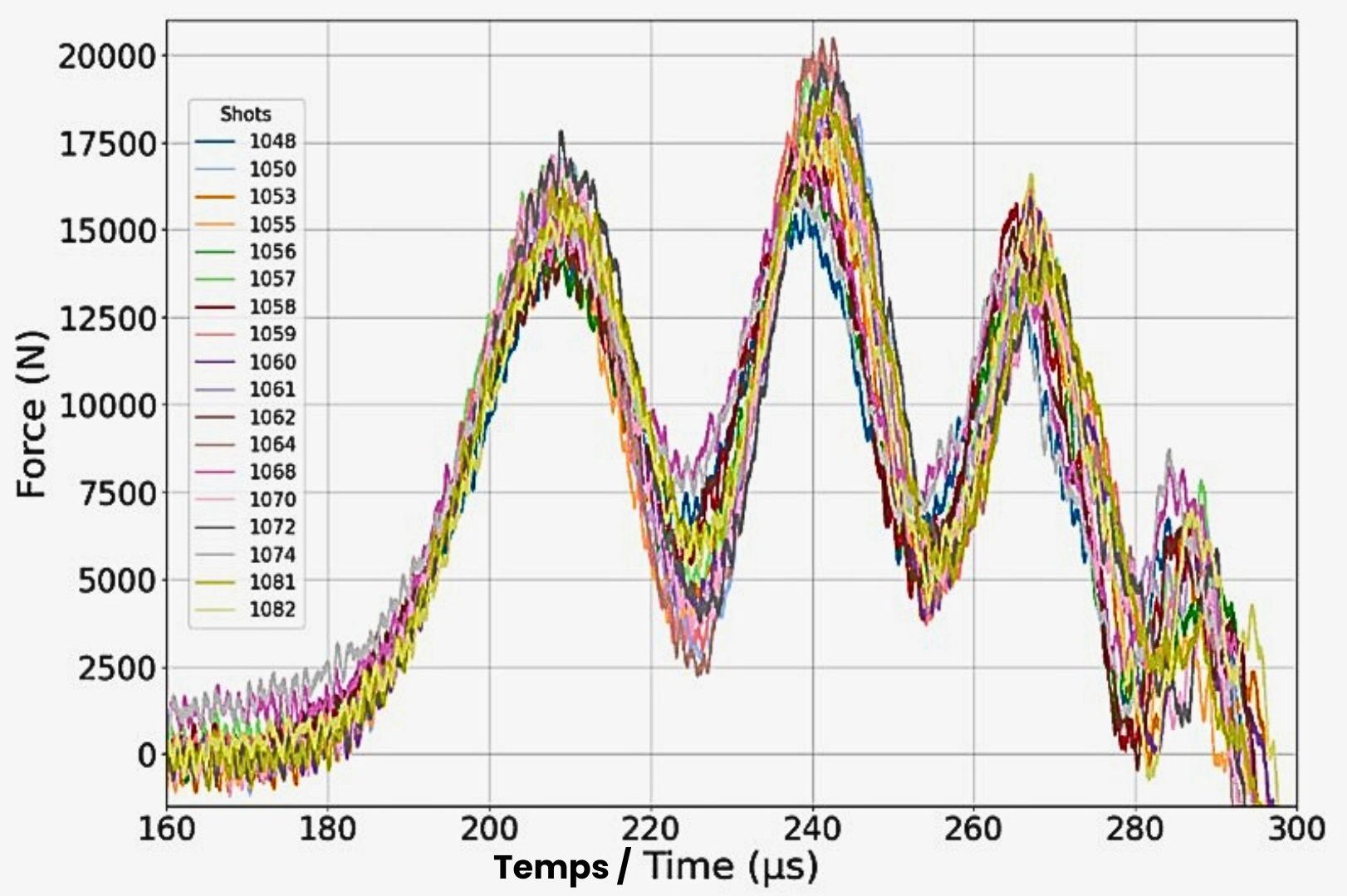

The DFH-KST model was implemented in the CEA's EUROPLEXUS software and made it possible to predict the temporal evolution of the impact force of water ice pellets as a function of their impact angle and velocity. These experimental and numerical results were detailed in the reference journal on impact loadings [1]. This work experimentally validated the use of a damage model for brittle materials under test conditions similar to those present in ITER.

The next step for PTC-DeFI was to measure the impact force of cryogenic solids made of hydrogen, neon, deuterium, or a mixture of these materials. The CEA-Irig/DSBT test bench was specially designed to produce these solids by in-situ desublimation, then propel them with a gas gun at velocities around 500 m/s. To characterize the impact of these cryogenic solids, researchers have developed an acquisition system capable of recording strain data up to 1 MHz and filming the impact up to 1 million frames per second.

Such a system for measuring the impact force of cryogenic solids is unprecedented. Experimental campaigns were conducted using the formation and acceleration parameters required for ITER. A reproducibility study involving 18 solid hydrogen shots, formed and accelerated according to the same parameters using a control system developed by DSBT, yielded promising results for the study of cryogenic solid impacts. These initial results highlight important parameters that need to be controlled, both in terms of the experimental setup (bar diameter, acquisition system) and the manufacturing parameters of cryogenic solids (temperature, pressure, and injection flow rate). We have already demonstrated the ability to film the impact of solid hydrogen pellets launched at 500 m/s (Figure 1) and to measure the temporal evolution of their impact force (Figure 2).

The results are currently being analyzed, and this experimental campaign will be the subject of a new publication. These promising initial results have led to the award of a European EUROfusion Engineering Grant to extend the PTC's work and expand the predictions of current models on inclined plates, thus approximating the actual geometries present in ice injection systems in magnetic confinement fusion reactors such as ITER or the future EU-DEMO demonstrator.

Figure 1: Sequential images of the impact of a solid hydrogen pellet at 500 m/s

Figure 1: Sequential images of the impact of a solid hydrogen pellet at 500 m/s

Figure 2: Impact force evolution over time for a series of 18 solid hydrogen shots at 500 m/s

Figure 2: Impact force evolution over time for a series of 18 solid hydrogen shots at 500 m/s

This work has led to the development of instrumental devices and numerical models specifically dedicated to the fragmentation of cryogenic solids injected into fusion reactors. More generally, a better understanding of the mechanical properties of cryogenic solids will make it possible to predict their behavior during impacts and slides that occur during injection. Looking ahead, plans are in place to study the fragmentation process of cryogenic solids as a function of the angle of impact and manufacturing parameters.

Collaboration

- Institut Géosciences et de l’Environnement, CNRS

- Laboratoire Sols, Solides, Structures, Risques, UGA

Fundings