The efforts of the Grenoble-based team within the framework of the European Battery Hub have been published in Advanced Energy Materials, a high-impact peer-reviewed journal, offering a unique insight into a matter shrouded in mystery. In fact, the study on overcharged batteries is currently based on post-mortem analyses, or on several successive stages of degradation, but the exact kinetics at play remain unknown.

A several-hour experiment

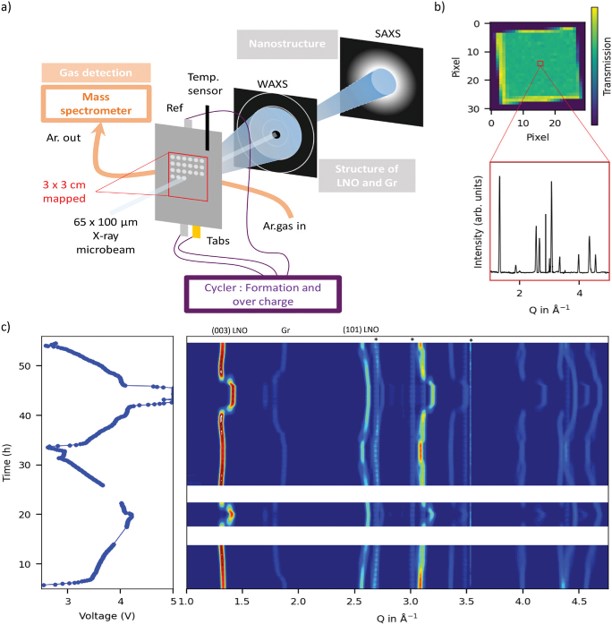

To uncover these reaction kinetics, the experiment was carried out at the Synchrotron on a battery in operando mode. This was done over a series of several-hour charge and discharge cycles followed by an overcharge phase, bringing together several methods. Two X-ray techniques, diffraction and small angle scattering, were used to examine the structural evolution of the electrode materials, while gas detection, particularly for oxygen, was employed to identify irreversible changes to the structures. The battery's functioning was also observed through electrochemical analysis.

Mapping Reaction Mechanism During Overcharge of a LiNiO2/Graphite–Silicon Lithium‐Ion Battery: A Correlative Operando Approach by Simultaneous Gas Analysis and Synchrotron Scattering Techniques

“Bringing together all these methods is a first. All the signals must be synchronized, as well as the measuring instruments, working well together. This means coordinating an interdisciplinary team of engineers, electrochemists and physicists," says Sandrine Lyonnard, CEA-Irig's specialist in operando studies at the Synchrotron.

Tracking the battery without damaging it

The battery also needed to be “scanned" using a small beam to check for any local heterogeneities and to ensure that the X-rays did not damage the system as the experiment progressed. Measurements were therefore taken using fast scanning without stopping at a specific point, i.e. in “flying mode". A hardly irradiated control area served as a baseline for proving the lack of deterioration associated with the imaging conditions.

“We have observed a 3.7 V high-energy density Li-ion battery with a chemical structure similar to those in electric vehicles. Gas emissions, measured in PPM, indicated the onset of irreversible changes to the electrode material," according to Lise Daniel, engineer-researcher at CEA-Liten and degradation mechanisms specialist.

Cross-degradation between the cathode and anode

The team made many new discoveries, including the presence of cross-reactions between the cathode and anode, where gas emissions from the former interacted with the latter, which, in turn, also started producing gases.

They also noticed that gas bubbles are able to isolate electrode materials locally and slow down lithiation. This phenomenon was mostly observed in “faulty" areas, characterized by a lack of materials, the presence of pollution, or allowances due to the manufacturing process— “more than enough reasons to improve quality controls in the factory", for Lise Daniel.

The researchers then went on to conclude that “these complex experiments at Synchrotron have pushed the boundaries of characterization: we are now able to probe a battery using ultimate spatiotemporal solutions. This has paved the way for an entirely new line of work in hyper-resolution rapid diagnostics, impacting all manufacturers in the sector."

Ref : Advanced Energy Materials, Volume: 15, Issue: 15, First published: 20 December 2024, DOI: (10.1002/aenm.202404080)