For researchers in the field, developing a reliable method to determine the state of health of Li-ion batteries during use is like finding the holy grail. This information is essential for estimating the remaining lifespan of cells, optimizing their management to extend their useful life, and thus designing longer-lasting batteries.

Real-world data scarce and insufficient

Nonetheless, many barriers stand in the way of achieving this technical goal. Battery degradation is linked to a range of interconnected factors such as temperature, applied current level, SOC range, cycle patterns, etc. These factors must then be prioritized and their multiple interactions analyzed. Moreover, aging studies take several years, are expensive, and involve too few batteries to be statistically significant.

Lastly, Battery Management Systems (BMS) are designed to monitor cell safety and autonomy, but rarely their state of health.

Interpretable results finally produced with physics-informed machine learning

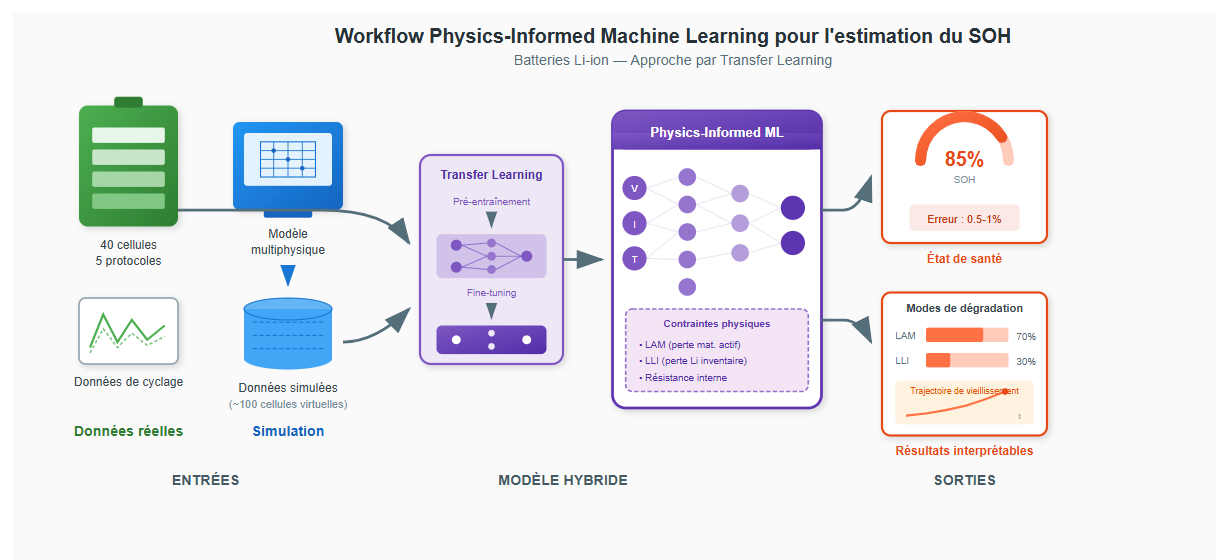

That's why the results of this joint project by the Liten and Leti team are so impressive. They have developed a workflow to estimate state of health based on actual data from just 40 cells, using five cycling protocols. What sets this method apart? The combination of two “physics-informed" machine learning models with transfer learning techniques.

“Rather than operating as a black box, these models incorporate physical data on the types of cell degradation," explains Marion Chandesris, a researcher at CEA-Liten. “These results can therefore be interpreted: my battery has lost 15% of its capacity, and I understand why."

|

Figure: Workflow Physics-Informed Machine Learning for estimating SOH

Error rate between 0.5% and 1%

And that's not all: this transfer learning workflow also draws on a range of simulated data from a multiphysics cell model. This provides as much data as a typical aging study on a hundred cells, measuring 1,000 intermediate states for each cell. “This increase in scale partly explains why our workflow is so accurate: the average error rate of between 0.5% and 1% is groundbreaking," says Vincent Heiries, a researcher at CEA-Leti.

What's the next step for this research? “We would like to move forward from estimating a battery's current state of health to predicting its future health trajectory, and thus extending its life," explains Marion Chandesris. “This may involve using other, more recent and more powerful deep learning algorithms."

According to Vincent HEIRIES, studies suggest that through optimal management, batteries could last twice as long. The potential for improvement is therefore huge.