RESEARCH PROGRAMS

Study of gasification kinetics and characterisation of physical and chemical phenomena

Study and characterisation of different synthesis gas quench systems

Study of innovative high pressure injection systems

Study of gas filtration and purification

EQUIPMENT CHARACTERISTICS

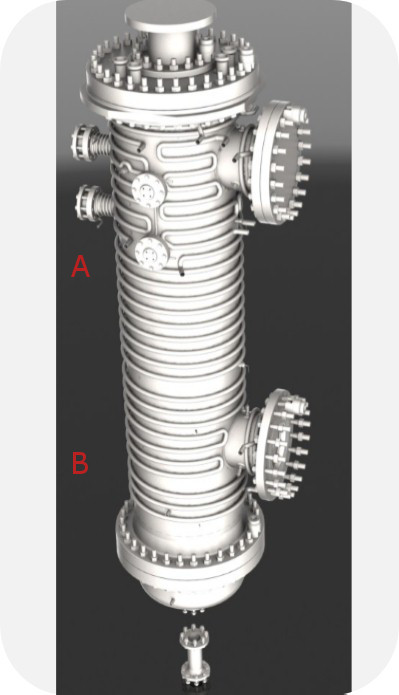

Reactor zone (A)

- Maximum temperature: 1500°C

- Pressure: 10-30 bar

- Maximum thermal output: 150 kW

- Heating by oxycombustion of:

- Natural gas (allothermal mode)

- Biomass (autothermal mode)

- Mass flow: 10-50 kg/h

- Feedstock : raw or torrefied wood mixed with agricultural residues or non-hazardous wastes

- Particle size: < 500 µm

- Moisture: < 10%

- Injection carrier gas: N2 or CO2

- Reactive gas: O2, H2O, natural gas

Quench zone (B)

Water or solid injection quench

Slag collection at the bottom of quench zone

INSTRUMENTATION

Wall and gas temperature measurement (thermocouple and pyrometer)

Mass flow measurement (solid et gas)

Measurement of major gas (CO, H2, H2O, CO2), minor gas and tar concentrations (tar protocol); tar measurement by SPA (Solid Phase Adsorption) sampling and quantification by gas chromatography