Adaptable, multi-functional coatings

Polymer-derived ceramic coatings (PDC) have great potential to enhance the performance and durability of materials in demanding environments. They have unique thermal, mechanical and chemical properties, and are often used for their stability at high temperatures and excellent resistance to corrosion. Likewise, with regard to their application, the chemical nature of these coatings enables the use of traditional polymer shaping methods in addition to ceramic shaping methods, and also makes it possible to treat a wide range of parts in the process.

Over the past 10 years or so, CEA-Liten has been working together with its partners in the petrochemical, microelectronic and aeronautical industries to develop tailored solutions for a wide variety of materials, such as gray cast irons, stainless steels, aluminum alloys, silicon, and ceramics, among others.

ACHIEF project: technological advancements for energy-intensive industries with stringent requirements

The ACHIEF EU project has addressed a major challenge: the need to optimize the energy performance of energy-intensive industries by identifying levers for improvement, where possible. In sectors where energy consumption remains inevitable given the processes carried out, ACHIEF’s most notable goal is to increase the lifetime of industrial equipment by more than 20%.

As part of this project, CEA-Liten has focused much of its efforts on the issue of corrosion at the TÜPRAS oil refinery in Turkey, where components need to be replaced regularly–typically every 8 to 12 months– in the CCR unit (Continuous Catalytic Regeneration) due to severe hydrochloric acid (HCl) erosion of stainless steel tubes.

Thanks to recent CEA-led advancements, a highly corrosion-resistant coating has been developed with a formulation suitable for automated spray applications, and the findings from full-scale parts testing have been promising: after 9 months of industrial trials, only slight damage to the tubes was detected during an expert assessment. This means that their lifetime could easily be doubled.

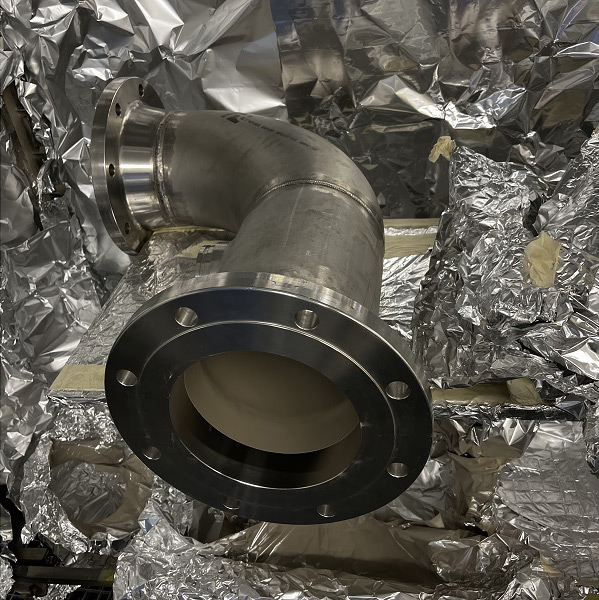

Coated stainless steel tube in a spray booth chamber. Credit ACHIEF.

Great prospects for industry

The ACHIEF project has demonstrated the industrial benefits of PDC coatings in improving the durability of equipment subjected to extreme operating conditions. The potential of these materials to protect against acid corrosion has been proven, particularly when caused by the condensation of concentrated HCl at temperatures close to its dew point. Two patents have been filed for the deposition process and coating, respectively.

To learn more

Discover the latest developments in the ACHIEF project in/on: