MEMS Reliability

Wafer-level electrical characterization and analysis are essential to improve MEMS performance

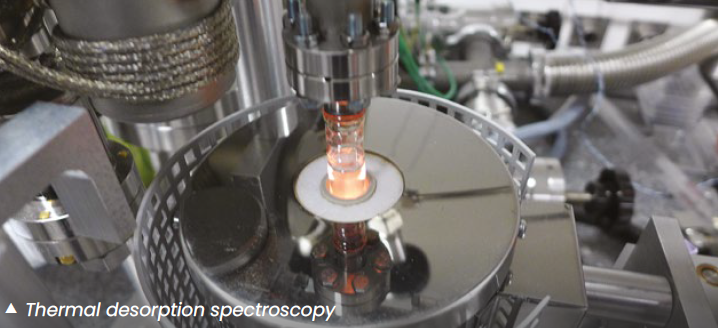

CEA-Leti is home to 70 wafer-level testing probers stations, both automated and semi-automated, for electrical behavior and reliability studies across temperature from -40 °C to 1,000 °C, and down to 2 Kelvin. Some probers also operate under vacuum pressures as low as 10-5 mbar. Complete RGA-TDS (residual gas analysis-thermal desorption spectroscopy) allows outgassing and sorption getter characterization under wafer-level packaging conditions, providing quantitative and qualitative data. This information, combined with CEA-Leti’s modeling and analysis capabilities, helps to improve chip functionality, performance and reliability.

What it can do

CEA-Leti’s wafer-level characterization capabilities allow device developers and manufacturers to understand what is happening inside MEMS devices: - Hermeticity of wafer level sealed cavities,

- Integrated vacuum lifetime,

- Quality factor and resonance frequencies of resonator modes,

- MEMS behavior studies in harsh environmental conditions,

- Deep defects analysis.

|

What makes it unique

CEA-Leti's unique range of wafer-level characterization equipment is backed by a team of experts and by characterization protocols developed at CEA-Leti to extract useful information about the physical phenomena involved in the components behavior. In addition to testing at much wider range of temperatures than standard wafer prober capabilities, CEA-Leti is also home to laser vibrometers, infrared microscopy and lock-in thermography, and the ability to measure and analyze residual gases under vacuum inside volumes as small as 1 mm3. CEA-Leti has also developed specific modelling capabilities that are particularly useful to improving device reliability. Finally, CEA-Leti has access to the CEA Nanocharacterization Platform for additional measurements, such as device morphology.

|

Working with CEA-Leti

CEA-Leti’s wafer-level characterization capabilities are of interest to foundries

and fabless companies seeking new insights into the electrical behavior and

reliability of their MEMS components.

Companies that partner with CEA-Leti gain access to a world-class slate

of wafer-level probers and other advanced characterization equipment,

all backed by CEA-Leti’s modelling and analysis expertise, plus access

to a wider range of measurements like those available at the CEA

Nanocharacterization Platform.