Toxicology is a key discipline for measuring the potentially harmful effects of chemical substances on human health or on the environment. It relies often on animal testing, which has important limitations. In addition to its legitimate ethical issues, this approach is not entirely reliable. Regardless of the animal species that are studied, results can never fully predict human reactions. Furthermore, toxicological analyses require specific skills, which requires industrial players to rely on specialized laboratories.

The TOXBOX project was therefore created to develop new solutions, New Approach Methodologies (NAMs)," prioritized by the European Commission as a way of improving the field of risk evaluation and of reducing animal experimentation. Funded by the European Union as part of the Horizon Europe program, and coordinated by Spatha Medical, a French SME, it was launched in January 2024 for a period of four years. Its aim is to develop a complete, modular system for conducting in vitro and in silico* toxicological testing to evaluate the toxicity of chemical substances in a simple, automated way.

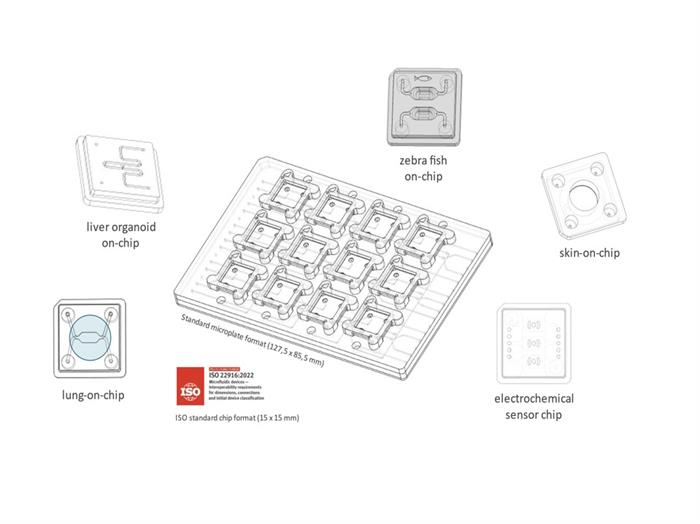

Ultimately, the device will give industrial players who develop new materials a toolkit that will enable them to adapt to every toxicological evaluation scenario. This modular toolkit will include sensors for measuring a range of biomarkers that are secreted by in vitro models, organoids-on-a-chip, which mimic organs such as the skin, lungs, and liver, or ecotoxicological models such as zebrafish embryos.

Modular microfluidic chips and electrochemical sensors

This ambitious project brings together 16 partners from 10 countries, each of which contributes its expertise, such as proficiency in toxicological test protocols and toxicity analysis, including AI-based methods, device ergonomics, or regulatory issues. CEA-Leti contributes its expertise in microfluidics to create the technological platform required for organoids-on-a-chip.

“We are developing modular microfluidic chips according to standardization guidelines on which we have been working for several years," said Remco den Dulk, microfluidics system engineer at CEA-Leti. “To do so, we rely on an FCB — a Fluidic Circuit Board — that we are developing as well. Much like a printed circuit board, it acts like a functional support to which modules such as organoid chips or sensor modules can be connected. This approach makes the system easy to modify, to use, and to operate automatically with a computer."

CEA-Leti has been developing electrochemical sensors that measure toxicity markers already in the context of PANBioRA, a previous European project. Currently, the aim is to improve the performance and robustness of the sensors while ensuring compatible with the FCB-based modular system, in order to continuously monitor toxicity parameters from the biological models.

Microfluidic chips that are ready to host biological models

CEA-Leti recently achieved an important milestone in the TOXBOX project. After a meticulous process of material selection, design, fabrication and biocompatibility testing, the CEA-Leti researchers sent its microfluidic chips to the partners that create the biological models. Early tests from our partners are promising and pave the way for the production of new batches of optimized chips that will be used for the intended toxicological evaluations.

The design phase for the electrochemical sensor is also complete. Researchers are now ready for the production phase, before they start to verify their performance.

“Still ahead is the development of the FCB and its control environment that will interconnect the different modules. It will act like a conductor for the entire microfluidics system," added Remco den Dulk.

This decisive step will combine the work of all project partners before the system will be integrated into the final system.

*by numerical simulation